Brief Course Outline

Part 1: SMT Overview

- SMT Process Steps

- SMT Passive and Active Components

- BGA, BTC, Flip chip and MCM

- Implementation Strategy & Summary

- Review/Questions/Answers

Part 2: Designing For Manufacturing

DFM for Lead Free Only

- Laminate & Surface Finishes

- Component Considerations

- Reliability Considerations

DFM for both Tin-Lead and Lead Free

- Handling of Moisture Sensitive Components

- Land Pattern Design

- Via Size, Spacing & Layer Count Considerations

- Testability

- Review/Questions/Answers

Part 3: Manufacturing Processes

- Adhesive and Its application

- Solder paste and its application

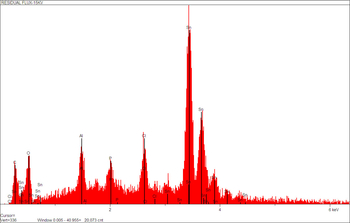

- Solderability & Soldering (Wave & Reflow)

- Application Specific Soldering

- Selective Soldering

- Vapor Phase Soldering

- Laser Soldering

- Low Temperature Soldering

- Mixed Alloy Soldering

- Flux and Cleaning and No Clean

- Quality Control, Inspection and Repair

- Review/Questions/Answers

Part 4: Brining it All Together: RootCause Analysis of Defects

- Examples of Defects related to Design

- Examples of Defects related to incoming materialsí

- Examples of Defects related to Manufacturing processes

- Key Strategies in preventing in design and manufacturing processes to prevent fieldreturns

Part 5: Discussion of defects you are experiencing.

- Discussion of Defects of interest to you

- Detailed (18 Page) Quiz to review the material covered

Registration is Open for SMT Course

Registration is Open for SMT Course

Ray Prasad will be teaching his flagship SMT course: